Executive Summary

As humanity scales up activity in Earth orbit and pushes farther into deep space, spacecraft face relentless environmental threats: micrometeoroid and orbital debris (MMOD) impacts, atomic oxygen erosion, thermal cycling, ultraviolet and ionizing radiation, and material degradation from harsh vacuum conditions. Traditional spacecraft surfaces and thermal blankets require conservative safety factors, redundancy, frequent ground‑interventions, or end‑of‑life replacements. Self‑healing spacecraft skins—multifunctional outer layers that can autonomously detect damage and restore structural integrity and functionality—promise to transform spacecraft resiliency. Drawing inspiration from biological systems and leveraging recent advances in polymer chemistry, composite engineering, nanomaterials, and even engineered living materials, self‑healing skins could extend operational lifetime, reduce maintenance and replacement costs, and enable sustained human presence beyond LEO where repair windows are scarce.

This article provides an in‑depth survey of the science, materials, architectures, and mission concepts for self‑healing spacecraft skins. We present mechanisms for self‑repair, radiation‑resistant design strategies, biomimetic inspirations, relevant demonstrations and prototypes, design tradeoffs, testing and qualification pathways, programmatic and policy implications, and a pragmatic roadmap toward operational adoption. The technical discussion balances chemistry and materials science with spacecraft systems engineering so readers from both domains can assess feasibility and prioritize research investments.

Why Self‑Healing Skins Matter

Spacecraft operate in an unforgiving environment. Key drivers for self‑healing skins include:

- Micrometeoroid and orbital debris (MMOD): Even millimeter‑scale particles impact at km/s velocities, producing perforations, delamination, and secondary fragmentation that can cascade into mission‑ending damage.

- Cumulative degradation: Ultraviolet (UV) radiation, atomic oxygen (in low Earth orbit), thermal cycling, and charge accumulation slowly erode surface coatings and materials, degrading thermal control, optical properties, and electrical insulation.

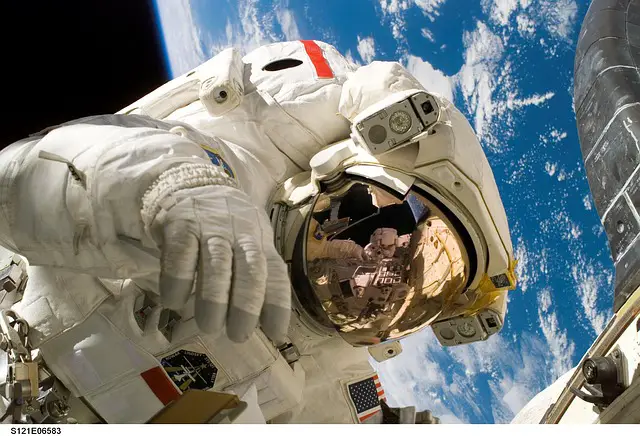

- Operational resilience: Deep‑space and long‑duration missions (Moon, Mars, cis‑lunar infrastructure) have limited options for resupply or EVA repairs. Autonomous or passive self‑repair systems increase survivability and mission assurance.

- Cost and sustainability: Extending satellite lifetimes reduces launching new replacements and lowers space debris generation.

Self‑healing skins aim to reduce vulnerability from single‑event damage and continuous degradation, enabling spacecraft that maintain thermal balance, communications performance, and structural integrity with minimal intervention.

Biomimicry: Nature as Blueprint

Biological organisms demonstrate diverse self‑repair strategies across scales. Biomimetic principles inform materials and architectures for spacecraft skins:

- Microcapsule healing (like blood clotting): When skin is cut, platelets and fibrin form plugs. Similarly, polymer microcapsules can release monomeric healing agents into cracks where they polymerize and restore mechanical continuity.

- Vascular networks (like plant vasculature): Plants and animals use vascular systems to deliver nutrients and healing factors. Engineered vascular networks embedded in composites can circulate repair fluids to damage sites, enabling repeated healing cycles.

- Dynamic bond chemistry and reversible adhesion (like protein folding): Some biological materials reconfigure or self‑assemble through reversible bonds. Polymers with dynamic covalent bonds or supramolecular interactions can autonomously reconnect under appropriate stimuli (heat, light, or catalytic activation).

- Living materials and adaptive growth: Certain organisms grow new tissue in response to injury. Engineered living materials (ELMs) leverage microbial or cellular systems to produce structural proteins or mineral phases in situ, offering an extreme but promising pathway for regenerative aerospace materials.

These concepts guide engineering implementations while acknowledging biologic systems trade off complexity, energy supply, and environmental sensitivity—factors that demand adaptation for the space environment.

Mechanisms of Self‑Healing: Intrinsic and Extrinsic Strategies

Self‑healing materials generally fall into two categories: extrinsic systems that store a healing agent and deploy it upon damage, and intrinsic systems that rely on reversible chemistry built into the material matrix.

Extrinsic Systems

Microencapsulation: Tiny capsules filled with a healing monomer or oligomer are dispersed within a polymer matrix. When a crack propagates, capsules rupture, releasing the healing agent into the damage zone where it encounters a catalyst embedded in the matrix and polymerizes, bonding the faces of the crack. Microcapsule systems are conceptually simple and have been widely demonstrated in terrestrial composites.

Vascular Networks: Multichannel networks embedded within composite laminates deliver healing agents from reservoirs to the damage site. Unlike microcapsules, vascular systems can be refilled—potentially enabling multiple healing events. Vascular heals can be passive (capillary flow) or active (pumped). They are analogous to human circulatory repair.

Phase‑Change Fillers and Melt‑Sealing: Materials can contain low‑melting fillers or phase‑change components that flow into cracks when heat is applied (from heaters or reentry heating for thermal protection systems), then solidify and restore mechanical properties.

Intrinsic Systems

Dynamic Covalent Chemistries: Polymers with bonds that can reversibly break and reform (e.g., Diels–Alder adducts, disulfide exchange, imine bonds) enable materials that can autonomously self‑repair under ambient or mild stimulation.

Supramolecular Polymers and Hydrogen Bonding: Non‑covalent interactions (hydrogen bonds, host–guest chemistry, π–π stacking) can produce materials that heal through reversible physical interactions without releasing external agents.

Ionomers and Metal–Ligand Coordination: Materials leveraging ionic clustering or metal coordination bonds allow reversible crosslinks that re‑establish under appropriate thermal or chemical environments.

Shape Memory Polymers/Alloys: Materials that recover a pre‑programmed shape upon thermal activation can close cracks or reseal surfaces after damage.

Each mechanism trades off healing speed, repeatability, mechanical recovery fraction, environmental sensitivity, and integration complexity. For spacecraft, environmental robustness (vacuum, radiation, temperature extremes) becomes a crucial selection criterion.

Radiation‑Resistant Materials: Protecting the Repair System Itself

Space radiation—composed of solar UV, energetic protons, electrons, and galactic cosmic rays (heavy ions)—can degrade polymers and damage electronic systems. Self‑healing systems must survive and function under radiation exposure. Strategies include:

- Intrinsic radiation‑tolerant chemistries: Polymers with aromatic backbones, fluorinated polymers, polyimides (e.g., Kapton), and high‑crosslink density systems resist chain scission and embrittlement better than simple aliphatic polymers.

- Nanofiller reinforcement and shielding: Adding high‑Z nanoparticles (bismuth oxide, boron nitride, tungsten) or 2D materials (graphene, hexagonal boron nitride—hBN) can both mechanically reinforce the skin and enhance localized radiation attenuation. Recent research demonstrates irradiation‑tolerant Ti/BN coatings with promising hardness retention after exposure. Combining fillers and matrix chemistry is an active area of research.

- Self‑healing chemistries with radiation stability: Select chemistries (e.g., certain dynamic covalent bonds) show greater radiation resilience. Engineering catalysts and healing agents that remain active after radiation exposure is critical.

- Layered architectures and sacrificial layers: Design skins with multi‑layer stacks where an outer sacrificial layer absorbs the worst of atomic oxygen and UV, while inner layers house the self‑healing infrastructure protected from direct space radiation.

- Active radiation detection and shielding control: Integrate dosimeters and active shutters or optically adaptive coatings that reduce exposure during solar particle events.

Selecting materials for both repair and longevity requires concurrent radiation testing—accelerated ion and gamma exposure—to evaluate degradation pathways and healing functionality after cumulative doses.

Architectures for a Self‑Healing Spacecraft Skin

A practical self‑healing skin is more than a single layer—it is a multifunctional system that integrates structure, thermal control, sensors, and repair capability.

Multi‑Layer Sandwich Architectures

Typical architecture includes:

- Outer sacrificial layer: Thin, replaceable, or easily reparable coating that protects against atomic oxygen, UV, and abrasive particulate impacts.

- Impact‑mitigating intermediate layer: Materials like aerogels or graded foams that absorb energy and slow projectiles, limiting penetration to deeper layers.

- Self‑healing structural matrix: Composite laminate or polymer layer containing microcapsules, vascular networks, or intrinsic healing chemistry that restores mechanical continuity and electrical insulation.

- Embedded sensors and electronics: Distributed fiber‑optic or printed sensor networks detect impacts, measure strain, and localize damage to trigger active repair routines.

- Inner thermal and EM control layers: Thermal blankets (MLI), EMI shielding, and electrical bus components that must be preserved.

Designing the interfaces—adhesion between layers, thermal expansion matching, and maintaining minimal mass—drives much of the engineering trade space.

Integrated Sensing and Autonomy

Rapid detection and localization of damage is necessary for targeted repair. Sensor suites can include:

- Distributed piezoelectric or acoustic emission sensors for impact detection. These capture transient stress waves from hypervelocity impacts and can triangulate location.

- Fiber Bragg Grating (FBG) networks embedded in composites for distributed strain and temperature sensing.

- **Printed or flexible electronic a