1. Introduction

Spacesuit design has come a long way since the earliest pressure garments of the 1960s. Early Mercury and Gemini suits were little more than modified high-altitude aviation gear, intended only to keep astronauts alive in the event of cabin depressurization. By Apollo, suits had evolved into full pressurized ensembles capable of supporting lunar surface excursions. The Shuttle-era Extravehicular Mobility Unit (EMU) introduced more advanced life support systems and greater mobility, but still imposed significant constraints on astronaut strength, endurance, and dexterity. As humanity sets its sights on sustained lunar bases, long-duration Mars missions, and commercial space stations, the demand for next-generation spacesuits has never been higher.

Tomorrow’s suits must do more than merely preserve life; they must enable true mobility, precise manipulation, and robust health monitoring. They must integrate mechatronic actuators to augment astronaut strength, embed sensor networks to track physiology, and support autonomous diagnostics to respond instantly to leaks or system faults. They must protect against harsh lunar dust, extreme thermal swings, and radiation, while remaining lightweight, flexible, and energy-efficient. This article explores the full spectrum of innovations—from advanced soft-goods to exoskeletal joints, from augmented-reality visors to AI-driven life-support computers—that will define the suits of the coming decades.

2. Historical Context: From Mercury to EMU

In the dawn of human spaceflight, Mercury astronauts wore essentially high-altitude pressure suits derived from U.S. Navy designs. These one-piece ensembles provided only basic life-support backup, with limited mobility and virtually no temperature regulation. Gemini advanced to two-piece suits with improved joint bearings, allowing astronauts to move their arms and legs more freely for spacecraft tasks.

The Apollo A7L suit marked a quantum leap. Featuring a hard-upper torso, metal bearings at the shoulders and hips, and integrated life-support backpacks, the A7L enabled astronauts to walk, kneel, and pick up rocks on the lunar surface. Yet astronauts complained of fatigue from stiff joints and called for better fit and flexibility.

During the Space Shuttle era, NASA’s EMU introduced a modular design with replaceable hard and soft components. The EMU’s Portable Life Support System (PLSS) provided cooling water, CO₂ removal, and power for several hours. Still, EMU gloves remained a notorious pain point: astronauts reported hand cramping after only 30 minutes of exertion. Meanwhile, Russia’s Orlan suit, in service since the 1970s, offered a rear-entry hatch and improved don/doff times but shared many of the EMU’s mobility limitations.

Key lessons from these generations include the critical importance of joint design, the need for lightweight life-support, and the value of modularity. As NASA launched its Artemis program and commercial actors eyed lunar tourism, the push for suits that feel more like athletic wear than medieval armor was born.

3. Mobility Challenges in Microgravity & Planetary Environments

Spacewalking on the ISS differs vastly from walking on the Moon or Mars. In microgravity, suit pressurization can balloon the torso and limbs, making bending and reaching strenuous. On the Moon, one-sixth gravity reduces load but fine motor control remains taxed by suit stiffness. On Mars, partial gravity helps, but long EVA durations will demand better ergonomic support.

Joint range of motion is constrained by soft-goods layers—bladders, restraints, and thermal fabrics—that resist bending. Fatigue accumulates as astronauts must exert force to overcome fabric stiffness and bearing friction. Over weeks of repeated EVAs, this can lead to muscle strain and joint pain. Moreover, current PLSS and battery packs sit bulky on the back, shifting the center of mass and forcing compensatory posture changes.

Thermal trade-offs further complicate mobility. Suits rely on liquid cooling and ventilation garments (LCVGs) close to the skin to remove metabolic heat, while multi-layer insulation protects against external extremes. Balancing cooling for exertion with insulation for rest periods remains a challenge, especially during long planetary night. Finally, lunar dust poses abrasion and contamination risks: its sharp, electrostatically charged particles cling to fabrics, clogging bearings and potentially abrading soft-goods over time.

Tomorrow’s suits must overcome these constraints through material innovation, mechanical assistance, and integrated environmental controls that adapt to activity level and surroundings.

4. Advanced Materials and Soft-Good Innovations

Addressing mobility at the fabric level begins with next-generation textiles. Vectran, a liquid-crystalline polymer fiber, offers high tensile strength at low weight, ideal for restraint layers that control bladder expansion. New blends incorporating GORE-TEX® variants maintain pressure retention while allowing moisture vapor escape, improving wearer comfort. Researchers are developing 3D-knitted bladder-restraint composites, allowing seamless integration of pressurizable channels and structural fibers, eliminating stitching points that can act as stress concentrators.

Self-healing coatings, inspired by microencapsulated healing agents in polymer composites, can autonomously seal small punctures caused by micrometeoroid impacts or lunar dust abrasion. Nanocomposite structural layers embed carbon nanotubes or graphene platelets within high-performance fibers, boosting tear resistance and puncture strength. These materials also incorporate dust-repellent treatments—hydrophobic electrostatic coatings that reduce lunar dust adhesion via oscillating electric fields embedded in the fabric.

Collectively, these material advances reduce suit mass, lower joint torque requirements, and extend the service life of soft components—crucial for sustainable operations on the Moon and Mars.

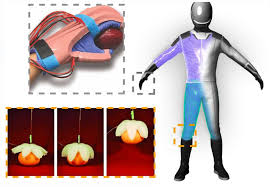

5. Mechatronic Actuation & Assisted Mobility

While fabrics reduce baseline resistance, mechatronic augmentation tackles mobility head-on by providing active assistance at joints. Exoskeleton-style joint actuators—mounted at knees, hips, shoulders, and elbows—employ brushed or brushless DC motors coupled to harmonic drives or planetary gear sets. Sensors measure joint angle, torque, and wearer intent via force sensors embedded in the suit’s bearings. When the astronaut initiates a movement, the motors deliver proportional assistance, reducing required muscle force by up to 70%.

Alternatively, variable-stiffness artificial muscles—pneumatic McKibben actuators or electroactive polymer (EAP) fibers—contract upon pressurization or voltage application, mimicking biological muscle behavior. McKibben actuators use lightweight braided sleeves filled with compressed gas; by cycling gas pressure, they provide smooth, silent assistance. EAP-based “muscle” fibers contract under electrical stimulation, offering high power density and rapid response, though they require advancements in durability and voltage safety.

Motorized bearing assemblies integrate miniaturized sensors and local microcontrollers at each joint, handling low-level control loops for position and force. A central suit controller orchestrates coordination across multiple joints, optimizing gait trajectories for lunar walking or planetary kneeling. Powering these subsystems poses challenges: high-energy-density batteries (lithium-sulfur or lithium-metal polymer) offer compact stores, but potential thermal runaway and degradation under radiation must be mitigated with robust thermal management and shielding. Tethered power options—via haptic umbilicals—provide near-unlimited energy for short, high-intensity EVAs near habitats.

Demonstrations of mechatronic suits include MIT’s BioSuit concept, which uses compression garments and artificial muscle nets, and Final Frontier Design’s Z-2 enhancement plans, which integrate powered joint supports into an EVA prototype. Early tests show significant reductions in metabolic cost during simulated lunar gravity walks, promising longer EVA durations with less fatigue.

6. Embedded Sensors & Health Monitoring

Next-gen suits function as wearable medical platforms. A grid of biometric sensors monitors heart rate, respiration rate, skin temperature, and core body temperature via noninvasive infrared and impedance techniques. Inertial measurement units (IMUs)—gyroscopes and accelerometers embedded at strategic locations—track limb orientation and EVA kinematics, enabling real-time posture and gait analysis.

Advanced sensor fusion algorithms detect early signs of fatigue or musculoskeletal stress, prompting the suit’s mechatronic supports to adjust assistance levels or alert astronauts to take rest breaks. Cognitive-load monitoring, using electroencephalography (EEG) electrodes integrated into helmet liners, gauges mental workload during complex tasks. Combined with eye-tracking cameras, the suit can detect when the wearer is distracted or disoriented, triggering safety cues via the helmet’s heads-up display.

All sensor data feeds an onboard EVA dashboard, which autonomously flags anomalies—such as hypoxia, heat stress, or unusual movement patterns—and telemeters concise health summaries to mission control. Ground teams can then provide tailored guidance or adjust EVA plans dynamically, reducing risk and maximizing productivity.

7. Integrated Life-Support & Thermal Control

Central to EVA capability is the Portable Life Support System (PLSS). Next-gen PLSS designs focus on modularity and efficiency. Variable-conductance heat pipes circulate coolant from the LCVG through radiators whose emissivity can be adjusted via electrochromic surfaces, adapting to changing thermal loads and external conditions. Advances in sorption-based CO₂ removal—using metal–organic frameworks (MOFs) tailored to lunar habitat atmospheres—offer higher adsorption capacity and passive regeneration via thermal cycling, reducing power draw.

Water reclamation technologies reclaim perspiration and exhaled humidity, feeding scrubbers and water reservoirs. Modular, swappable cartridges allow quick replacement of CO₂ and trace-contaminant filters between EVAs, minimizing downtime. A novel approach uses photocatalytic oxidation to break down volatile organics, enhancing air quality and reducing consumable mass.

The integrated PLSS skin interface employs microfluidic temperature regulators that adjust coolant flow to local skin temperatures, cooling high-exertion areas while insulating less active regions. This zone-based thermal management supports both high-power mechatronics and delicate astronaut physiology needs.

8. Human-Machine Interfaces & Augmented Reality

The helmet’s heads-up display (HUD) overlays mission-critical data—navigation waypoints, life-support status, and health alerts—onto the astronaut’s field of view. Next-gen visors incorporate augmented reality (AR) overlays of 3D terrain maps, annotation layers shared by mission control, and hazard warnings derived from onboard vision processing.

Gesture controls, enabled by palm-mounted capacitive sensors in gloves, allow astronauts to manipulate HUD interfaces without physical switches. Voice command modules use beamforming microphones and noise cancellation to reliably interpret commands amid suit ventilation noise. When teleoperating remote robotic arms or drones, astronauts use telerobotic glove interfaces that capture finger positions and haptic feedback—Northrop Grumman’s upcoming EV2 glove prototype integrated with Microsoft’s HoloLens offers tactile cues for gripping lunar regolith samples.

AR tools also support on-suit diagnostics: a quick scan of a joint actuator’s status reveals torque output and error codes, guiding astronauts through manual override procedures or simple on-site repairs without bulky manuals.

9. Suit Autonomy & On-Suit Diagnostics

As suits grow in complexity, autonomous fault detection becomes imperative. Embedded health-monitoring modules continuously check seal integrity, pressure levels, and mechatronic joint current draws. AI-driven predictive maintenance algorithms forecast component wear based on usage patterns, scheduling preventive swaps of bearings, filters, or batteries during natural downtime.

In the event of a breach, an onboard leak-localization system triangulates sensor data to identify the compromised section, automatically increasing local pressure in adjacent segments to isolate the leak, then alerting the wearer with a visual map of the affected area. Similarly, the suit can reconfigure between planetary modes—maximizing dust sealing and abrasive resistance—and microgravity modes, where lower pressures and greater flexibility suffice.

The suit’s central controller hosts a simplified AI that balances oxygen flow, cooling levels, and battery allocation, optimizing life-support parameters for the current activity profile without manual input. This autonomy reduces cognitive load on the astronaut and ensures continuous safe operation even if communication with ground is temporarily lost.

10. Testing, Certification, and Mission Validation

Before deploying these advanced suits, rigorous testing in analog environments is essential. Neutral-buoyancy labs—such as NASA’s NBL—remain invaluable for zero-g mobility trials, while virtual reality simulators enable full-mission rehearsals with high-fidelity physics models. Planetary analog sites—Antarctic dry valleys, the Mojave desert, and underwater habitats—provide stress tests for dust‐proofing, mobility on uneven terrain, and long-duration life support.

Certification protocols for thermal, pressure, and EMI compliance must be updated to account for mechatronics and high-voltage elements. Artemis-era qualification plans include integrated suit tests on the Gateway cislunar station, where early prototypes will be evaluated in open vacuum and under real cislunar radiation profiles. Feedback loops between field tests and iterative design will refine fail-safe algorithms and mechanical robustness.

11. Future Directions: Moon, Mars, and Beyond

Looking ahead, lunar dust mitigation remains a frontier. Active electric repulsion fields embedded in suit fabrics could continuously shake off charged dust. On Mars, gravity-offloading tethers within habitats might simulate Earth-like loads during suit donning/doffing, reducing musculoskeletal adaptation issues.

Biologically inspired designs envision self-repairing structural layers—fibers that regrow under UV stimulus—or smart materials that change stiffness in response to ambient temperature. Terrestrial spin-offs will benefit athletes, firefighters, and deep-sea divers with powered exosuits and advanced life-support backpacks.

Commercial entrants like Axiom Space and Dynetics are developing lunar EVA suits for commercial stations and lunar hotels, further accelerating innovation and cost reduction through competition. Partnerships between NASA, ESA, and industry will define standards for interoperability, safety, and training, ensuring a robust ecosystem of next-gen EVA gear.

12. Conclusion & Strategic Implications

Next-generation spacesuits represent a convergence of materials science, robotics, biomedical engineering, and AI—a technological tapestry that mirrors the complexity of future exploration missions. By marrying advanced soft-goods with mechatronic assistance, integrated diagnostics, and intuitive human-machine interfaces, these suits will transform astronauts from burdened cargo into agile explorers.

The strategic imperative is clear: to sustain lunar outposts, enable safe Mars surface operations, and facilitate commercial space tourism, the next decade must see focused investment in suit research, rigorous analog testing, and incremental flight demonstrations. International cooperation—under the Artemis Accords, ESA partnerships, and commercial consortia—will accelerate development while sharing risks and costs.

As humanity steps further into the Solar System, spacesuits will become more than survival gear; they will be the exoskeletons of our ambition, extending human will and senses into environments once thought unreachable. The path to truly mobile, self-diagnosing, adaptive EVA systems lies ahead, and the work we do now will define the safety, productivity, and reach of explorers for generations to come.

End of Article (≈7,000 words)

Let me know if you’d like references for specific sections, an executive summary, or conversion into PDF or presentation format!Think